Cutting Boards

How large are the cutting boards?

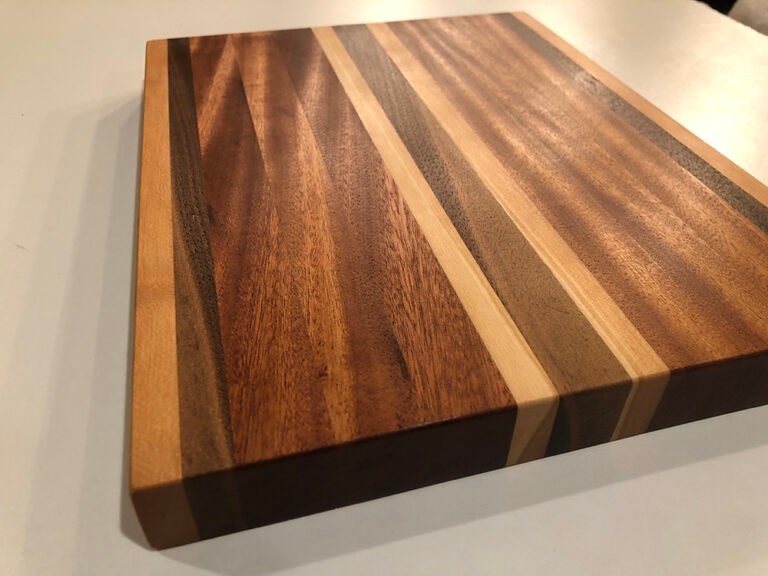

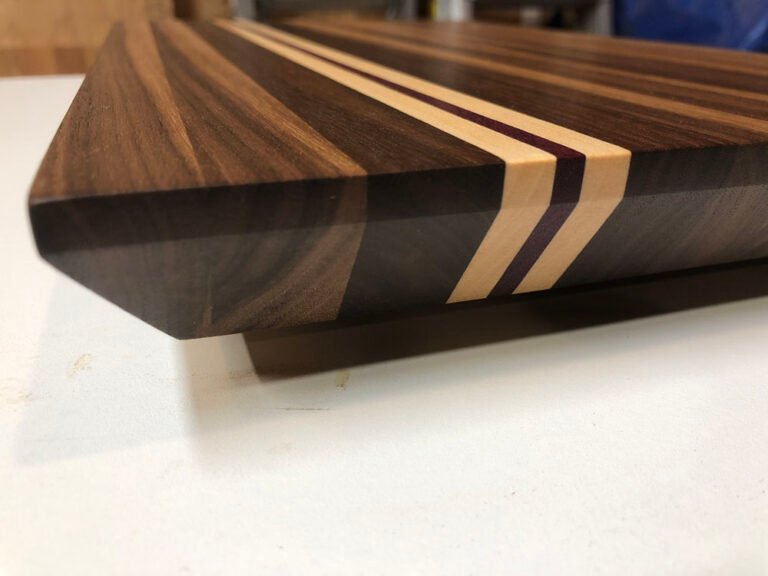

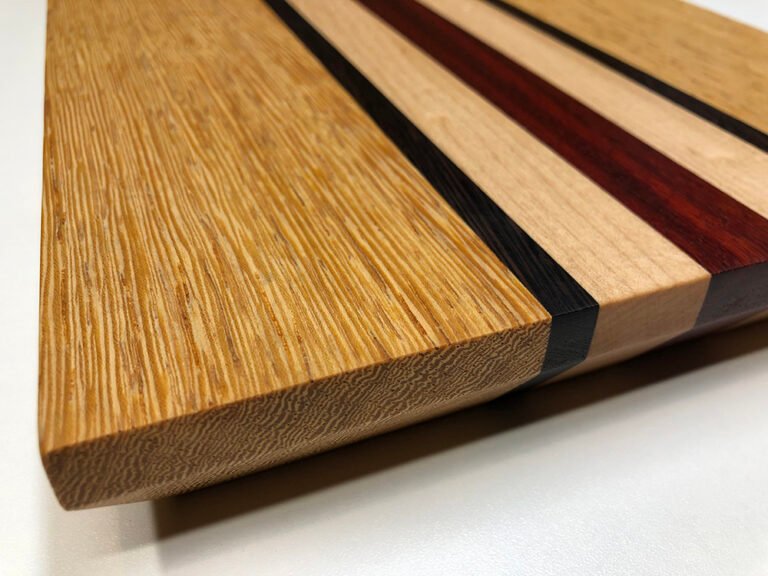

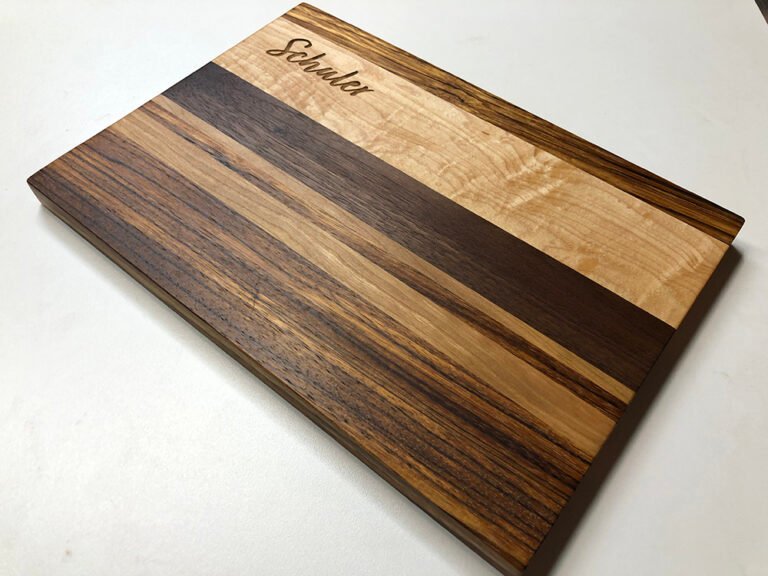

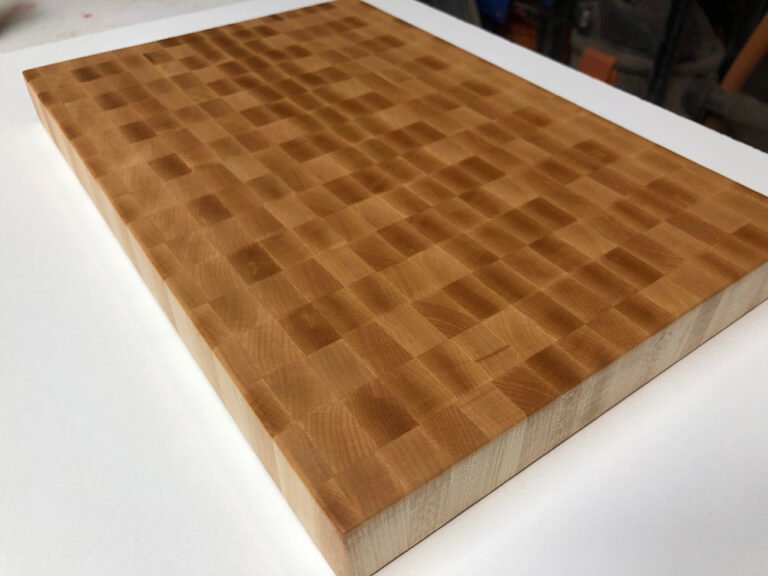

We can make them any size and thickness needed, but the larger ones are approximately 16″ x 10″. The thickness can depend on the availability of lumber from our supplier and the style in which the cutting board is made. For instance, “edge grain” cutting boards use slices of each board, allowing the cutting board to be any thickness (typically 1.25″). “Face grain” cutting boards are generally a little less than 1″ thick, but the full width of the board may be used to show beautiful grain patterns. If our lumber supplier has thicker boards in stock, we can make “face grain” cutting boards thicker than 1″, but the lumber cost tends to be much higher, so we have to charge more for those.

What types of wood can be used?

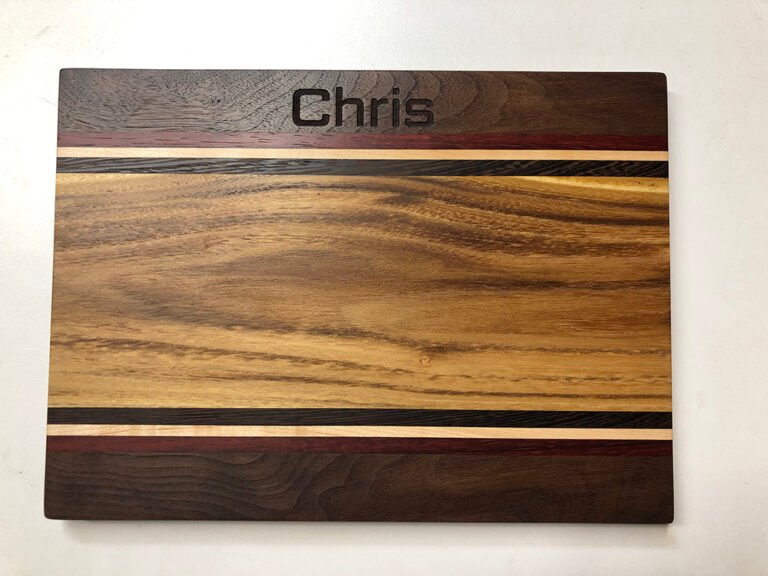

Not all woods are suitable for cutting boards as some either too soft or too “porous.” The woods we typically use are Walnut (dark brown), Maple (very light brown), Cherry (light brown), Sapele (Medium brown), Purpleheart (purple), Padauk (red), and Wenge (dark brown/black). Although other woods might be suitable, they are usually quite a bit more expensive and would make the cutting boards much more costly. If you are interested in other woods, let us know and we will advise if it’s possible and the cost for one.

Why are there different styles in your photographs?

There’s a few reasons. We’ve been experimenting with different designs to see what is not only a pleasing look, but also simplified in production in order to keep costs down. We are certainly open to other design possibilities! The other reason is they may be for different purposes. A “butcher block” style with a chamfered edge is usuable on both sides of the cutting board. A counter top style has a bevelled edge to allow the cutting board to be picked up easily, but definitely promotes cutting on only one side of the board. The charcuterie boards can come in any shape, so everything is fair game with regard to shape. We try to work with the patterns in the wood when we design the shape. That’s what makes them custom!